PO Box 112, Paradise Point, Queensland 4216, Aus

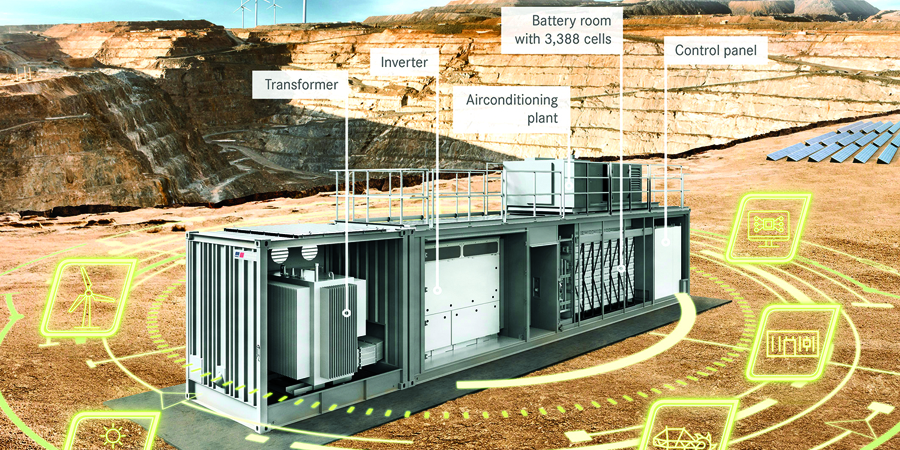

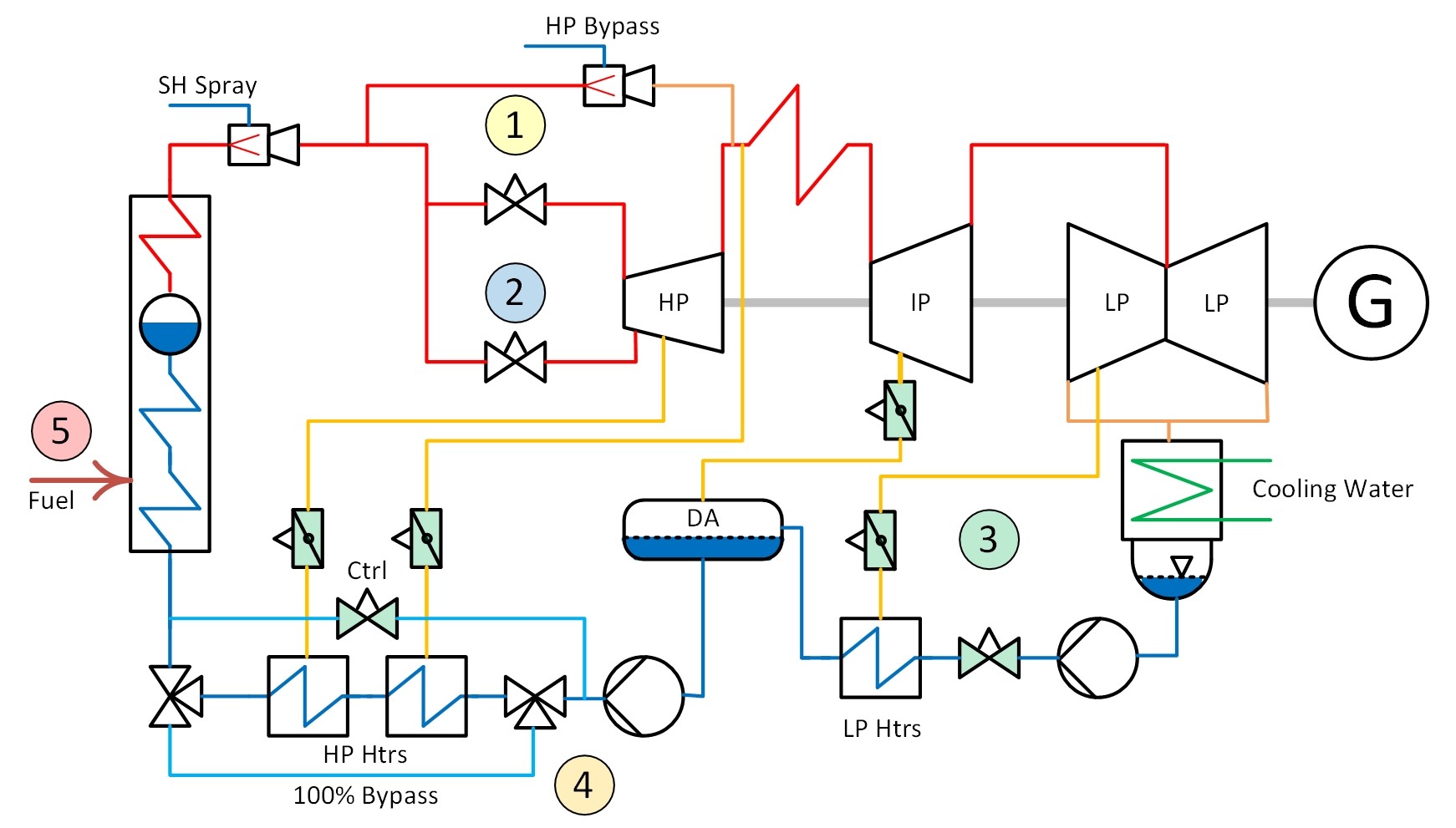

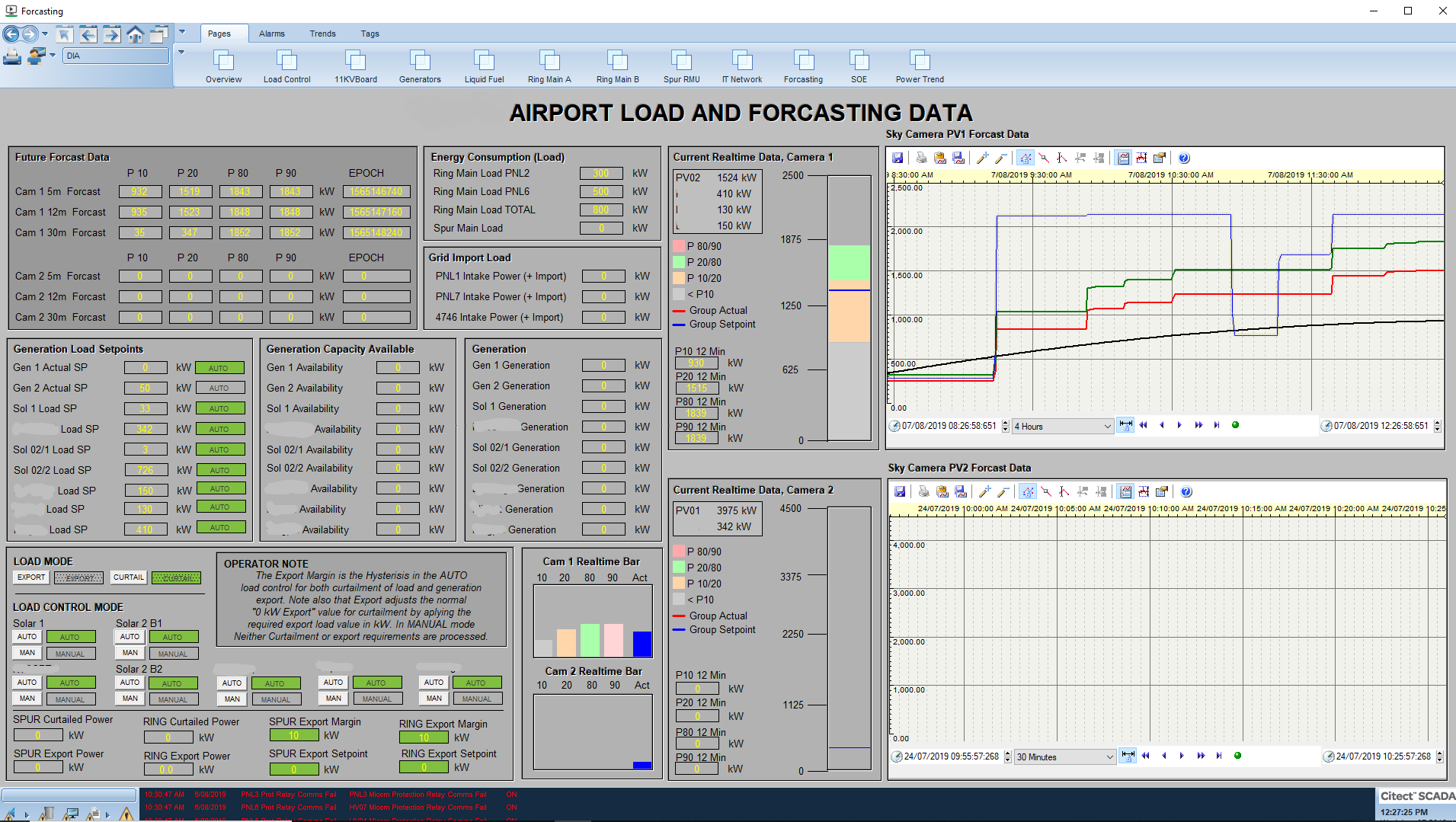

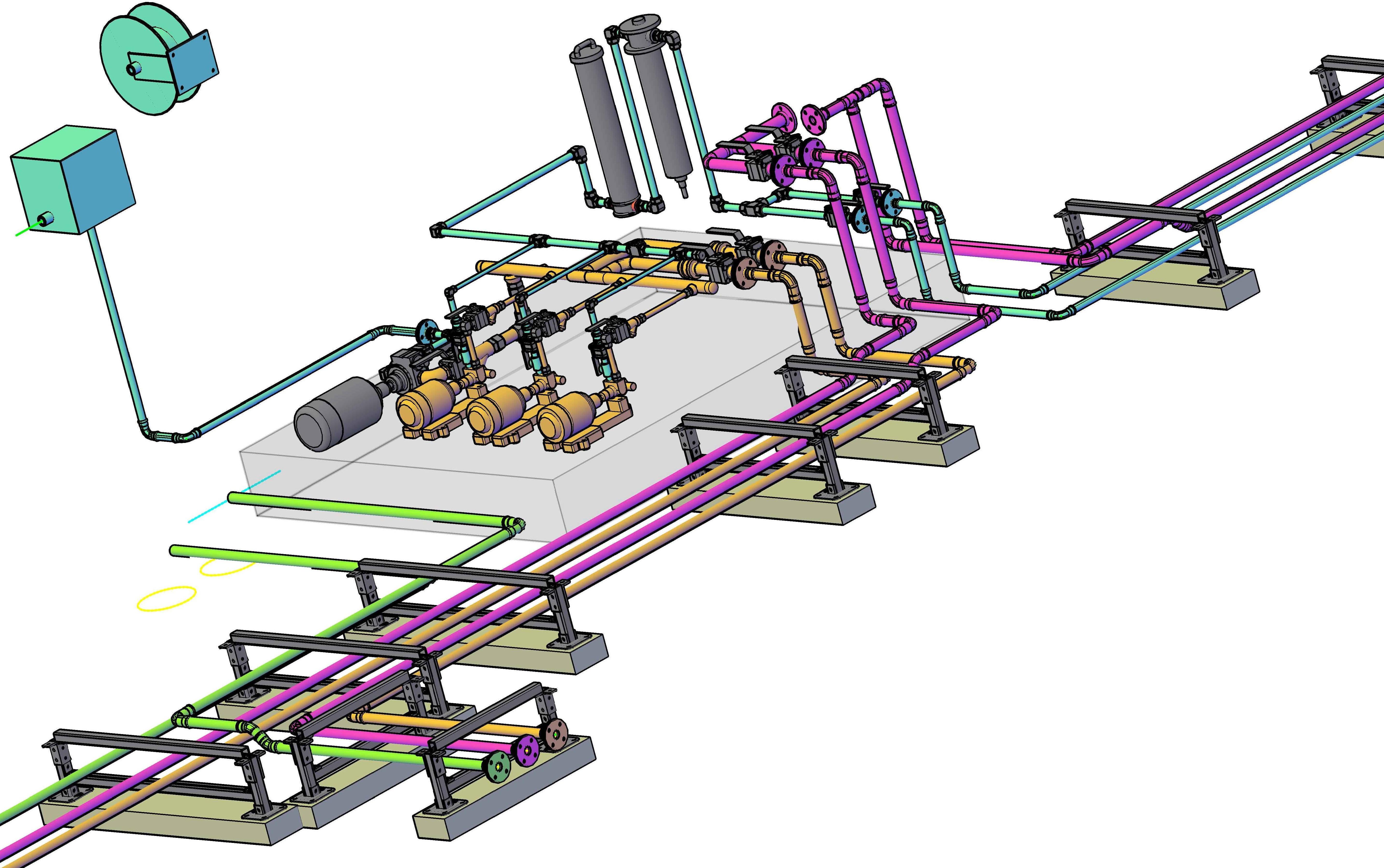

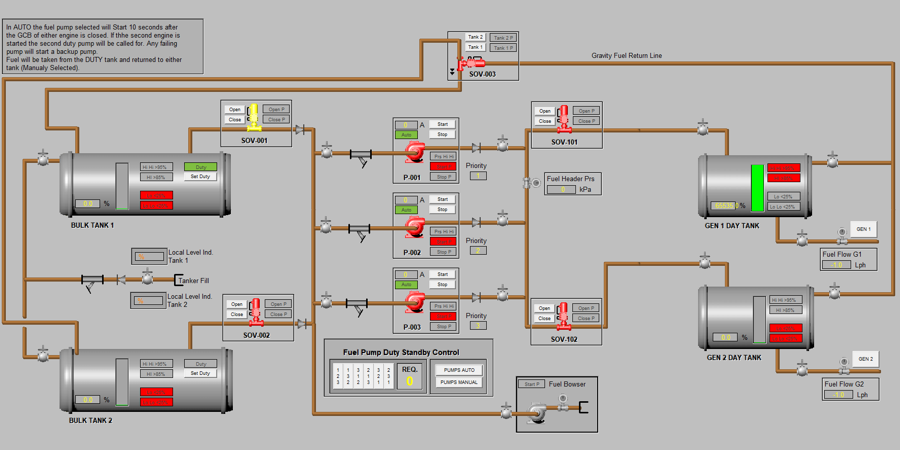

With renewable penetration in to the country’s grid and micro grid systems the use of battery energy storage is becoming more widespread. Gensrv are implementing Hybrid control systems to optimise a number of microgrid deployments. Here these systems manage the facility spinning reserve whilst not impacting reliability of supply. System owners can therefore implement more renewable within their system and the battery storage takes care of the volatility in generation. Furthermore, the implementation of the storage allows for the reduction in spinning reserve. In many cases these microgrids are operated at number of generators in N-1 thereby allowing for a single loss. The impact to OPEX is in both operation at lower efficiency and direct maintenance costs.