PO Box 112, Paradise Point, Queensland 4216, Aus

QUEENSLANDS NEWEST CCGT ONLINE

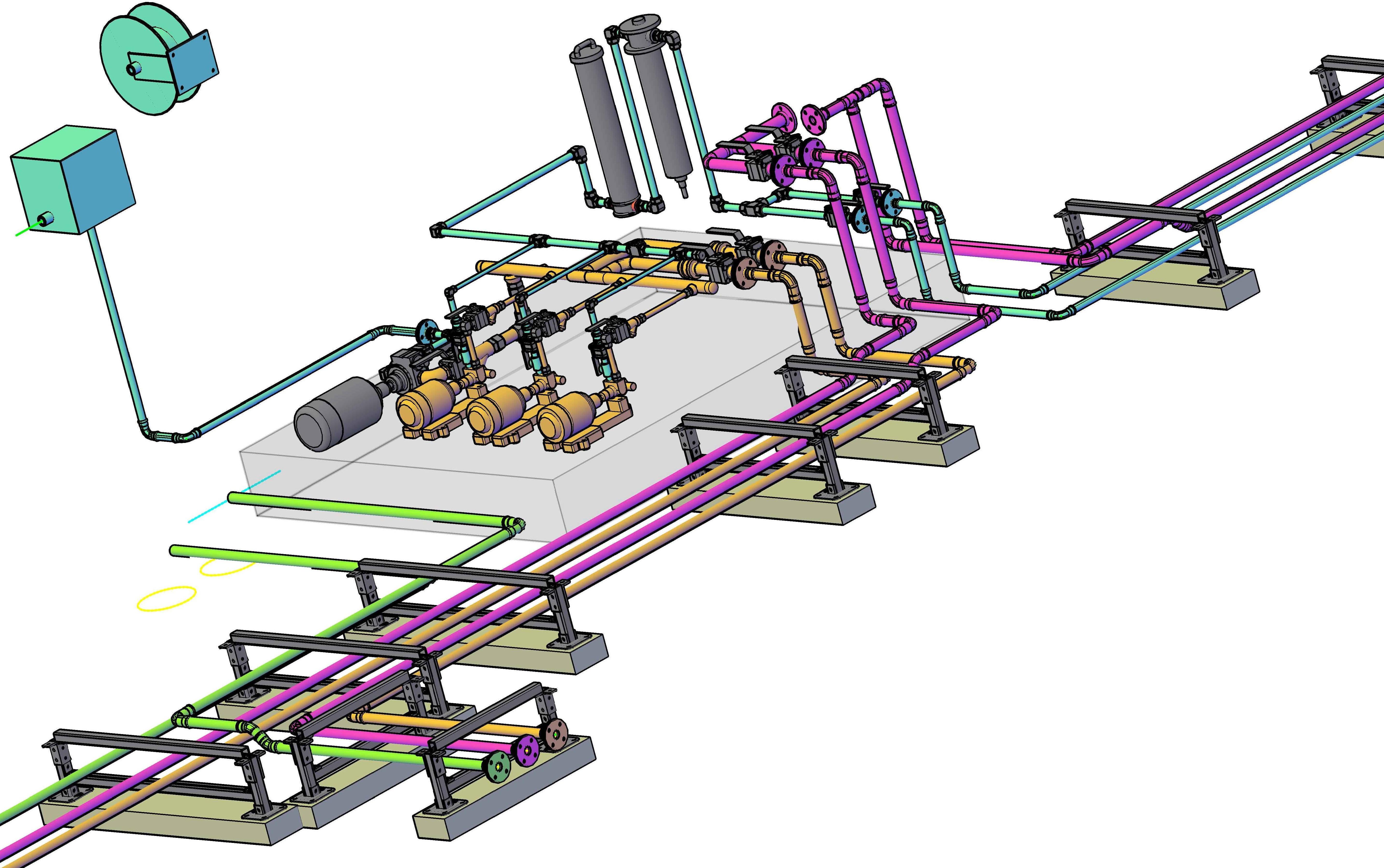

Conceived in 2011 by negotiation with current Gensrv staff. Diamantina CCGT was EPC developed by our Gensrv staff from concept through basic design and onwards to 85% completion and first firing of initial gas turbines. The plant was at that time constructed under an EPC contract by the CTEC Australia. Key staff from CTEC have integrated in to the Gensrv team bringing the same high levels of engineering knowhow and construction expertise to the group.

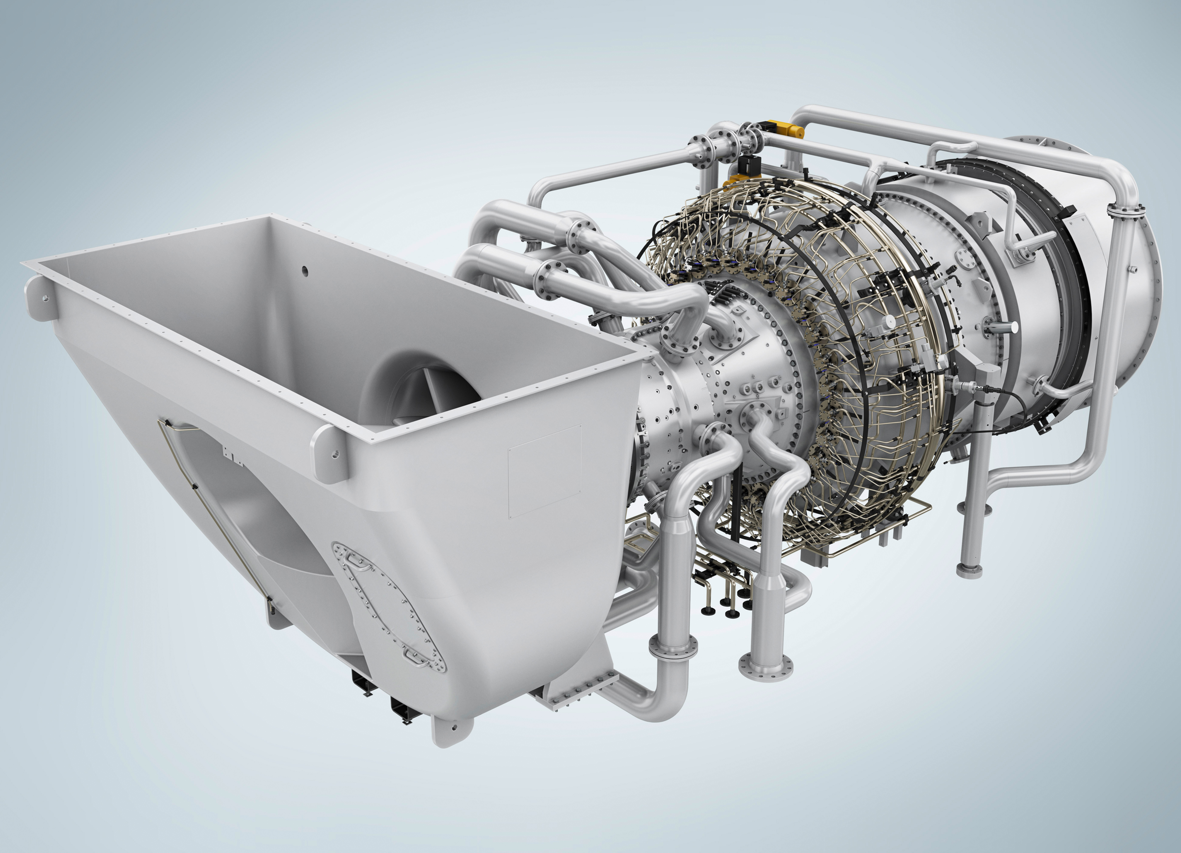

The Diamantina plant was negotiated as an EPC contract by Gensrv staff and was delivered under a multi sub-contractor model with Siemens taking primary responsibility for detailed design and supply of the power islands.

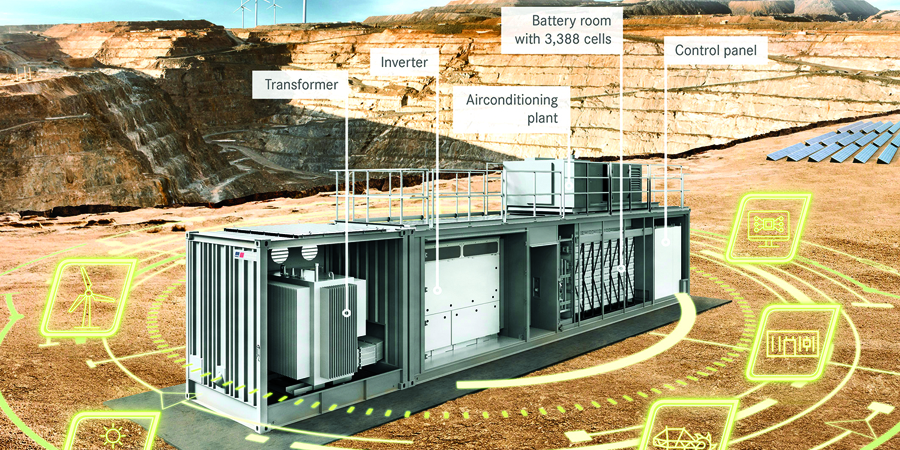

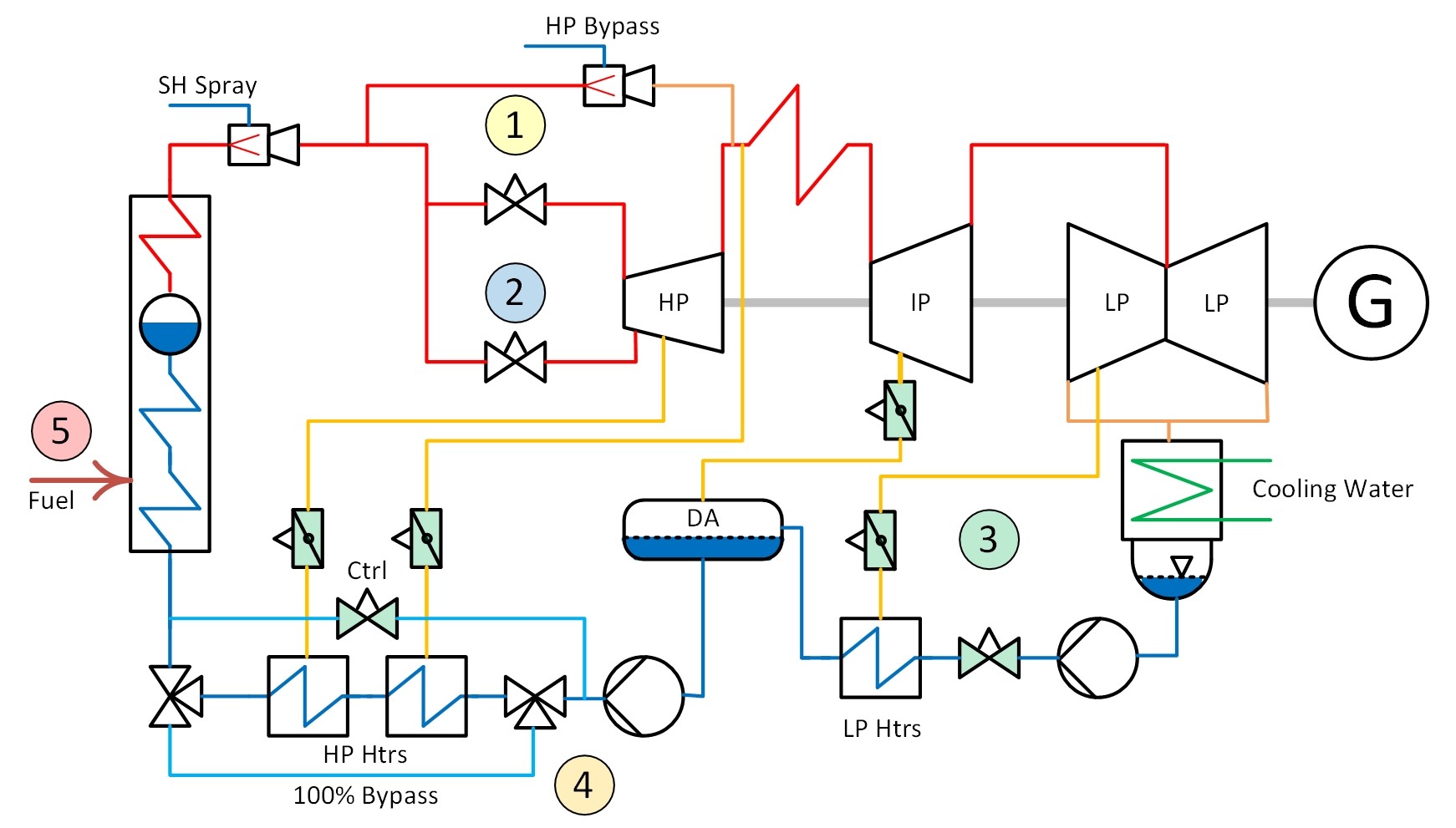

Diamantina is based on the Siemens SGT-800 gas turbine in combined cycle configuration. The plant comprises two identical CCGT blocks each having two by 40MW gas turbines, 2 by 2twin pressure heat recovery boilers and a single steam turbine. Each block is capable of generating ~125MW at >50% efficiency. To maximise the client’s ability to meet their power purchase obligations and also to achieve the highest plant output GT inlet chilling was added.

The use of chilling allows the gas turbines T2 temperature to be lowered to 15 DegC for ambient up to 40 DegC. This allows the plant owner to sell more output for the duration of the year instead of having the plant capped at the lowest output of the hottest day.

Another key feature in this plant is the interconnection of the two blocks and addition of supplementary gas firing. Each boiler is capable of another 33% output if required. Therefore, when a GT is out of service with its matching boiler. If required, the remaining boilers can be fired to raise the output of the steam turbines back to full capacity (remembering 1 GT and its boiler are out of service).