PO Box 112, Paradise Point, Queensland 4216, Aus

SCADA AUTOMATION IMPROVES AVAILABILITY

Gone are the days of Buttons and Switch’s. In almost all facilities we now use Distributed Control, Programmable Logic Controllers and Human Machine Interfaces. The primary advantage of this type of system is the ability to retain history. If we look at older control systems we could start, stop and monitor the process but we really had little indication of where the system variables were going or where they had been. In the event of a trip or failure we received some annunciation and alarm bells but little indication as to the root cause or sequence of events leading up to the trip.

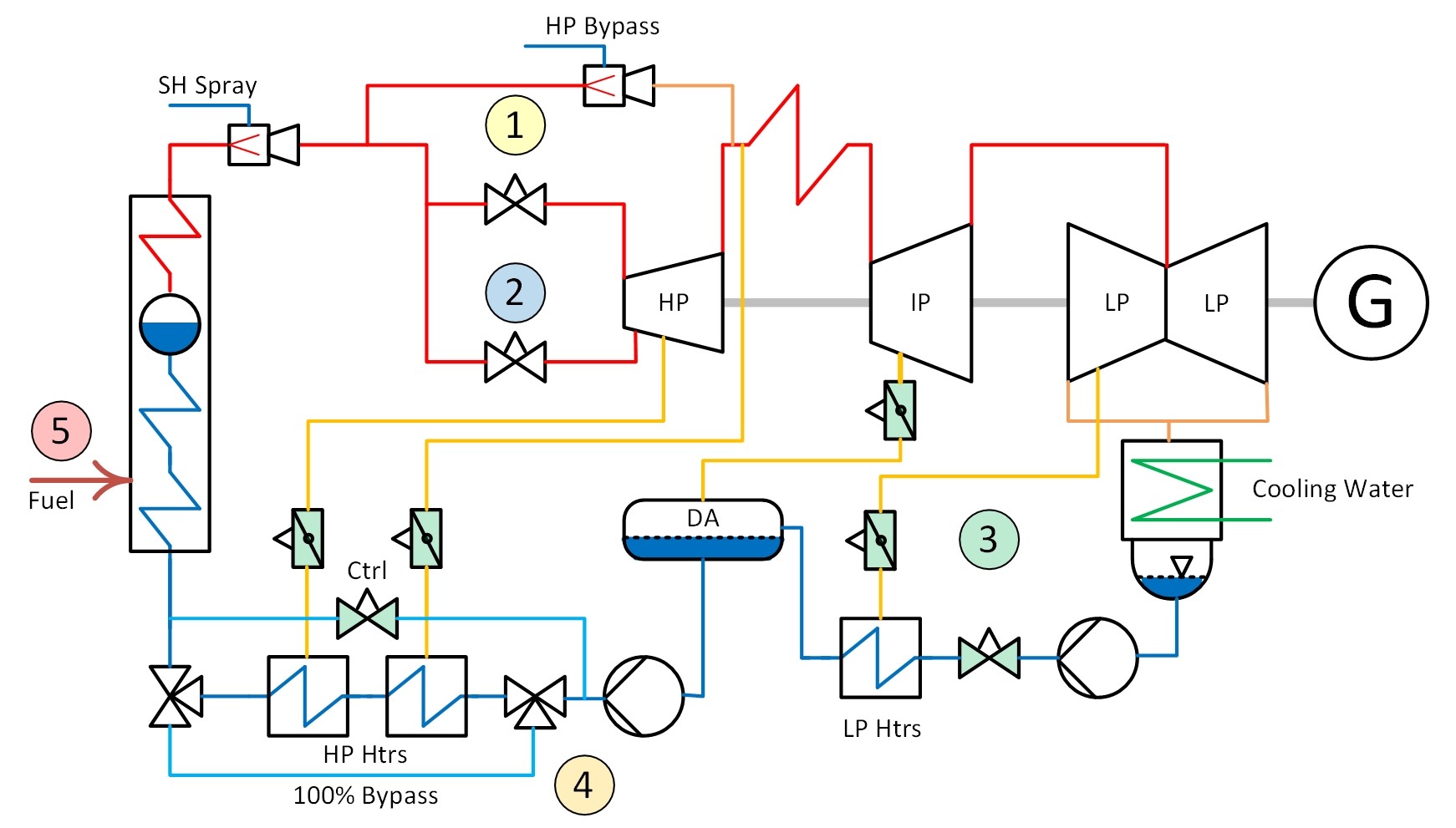

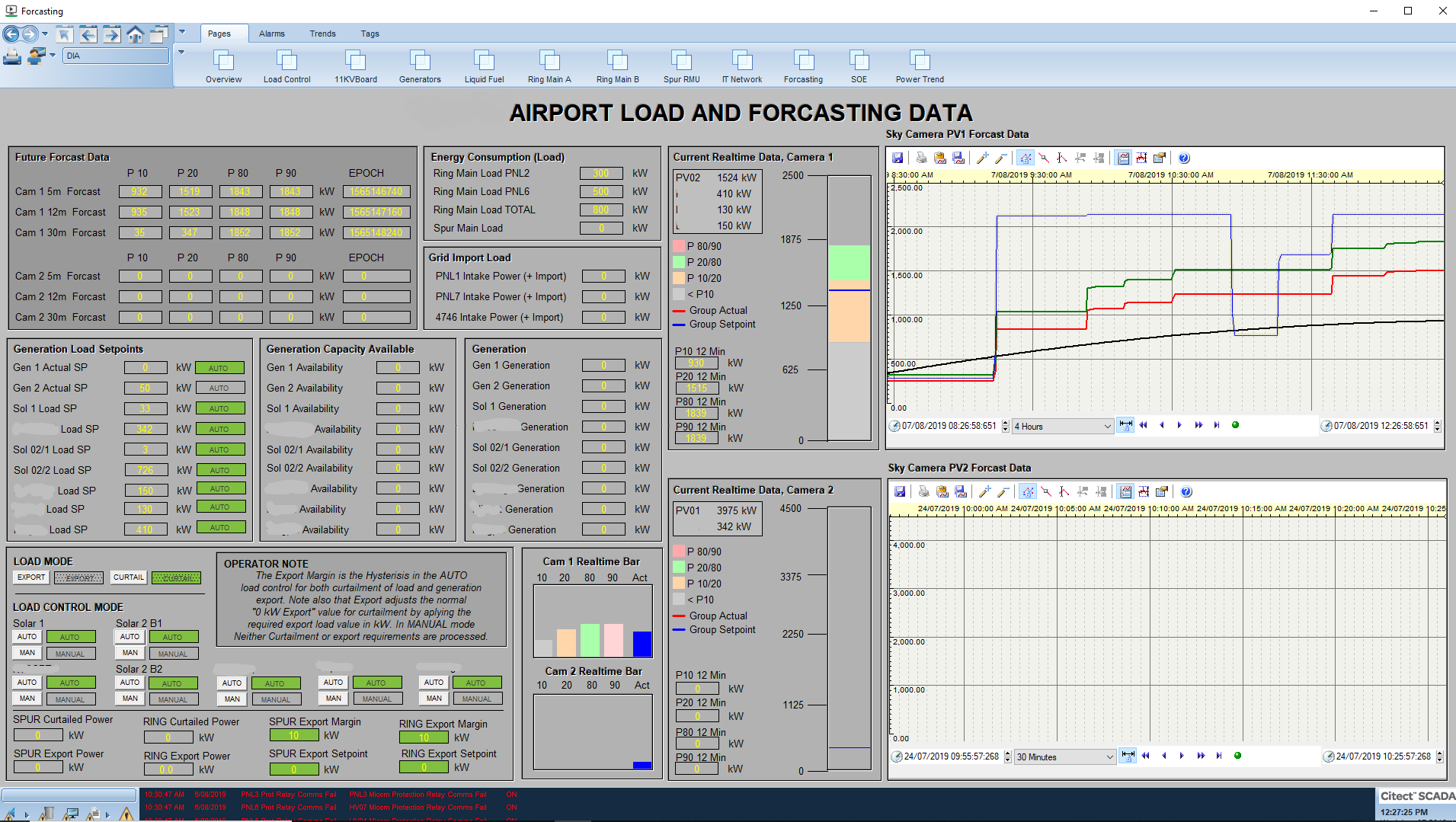

By adding a Computerised Control system, the data collected from a process can be archived against time and reviewed or trended allowing historical revenue. Typical operation is not done by looking at pictures representing the physical path but by monitoring of trend lines and data. In this way operators can spot changes in given parameters which may highlight a potential issue.

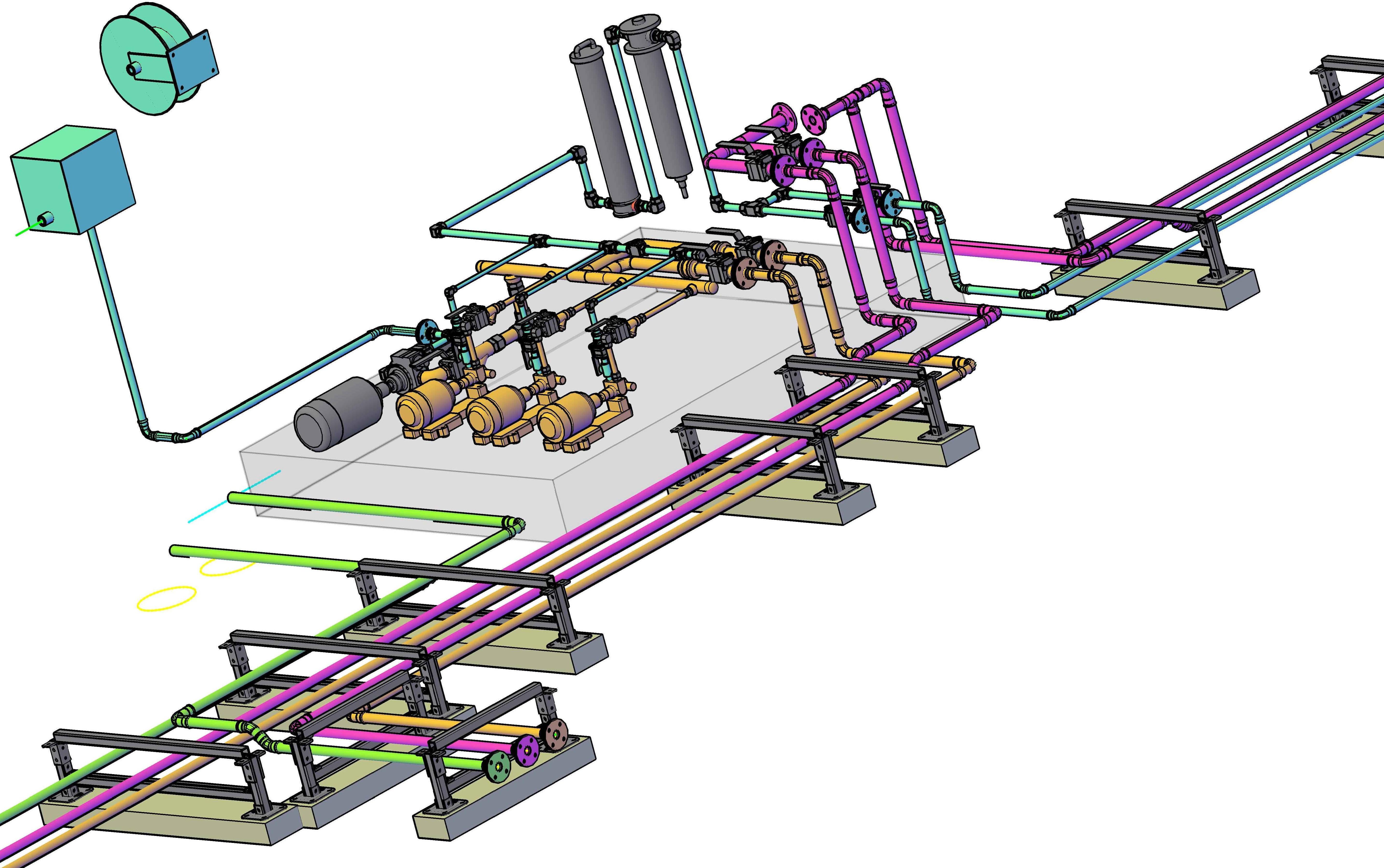

The DCS / PLC control system comprises a number of components in a hierarchical arrangement. At the machine level instrumentation collects raw data much as it did in the previous days. Most instruments now export this data as either 24Vdc signals or 4..20mA signals. These signals are received by Input / Output cards attached to a PLC or DCS controller. The Controller is programed in by the engineer and is able to perform logic and calculations based on the data received from the IO cards. For example, an analogue input process value can be compared with a set point and a PID controller used to drive an analogue output which moves a valve or adjusts a pump speed. In the same way digital signals can be monitored and devices started, stopped or alarmed on status change.

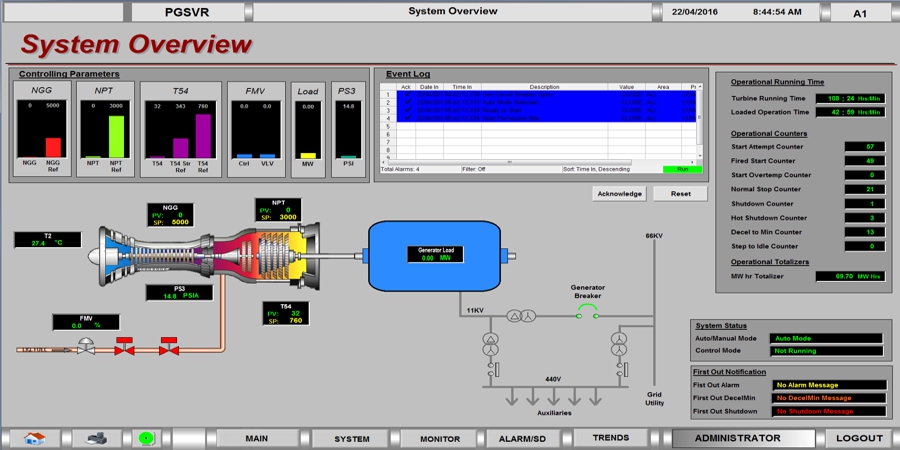

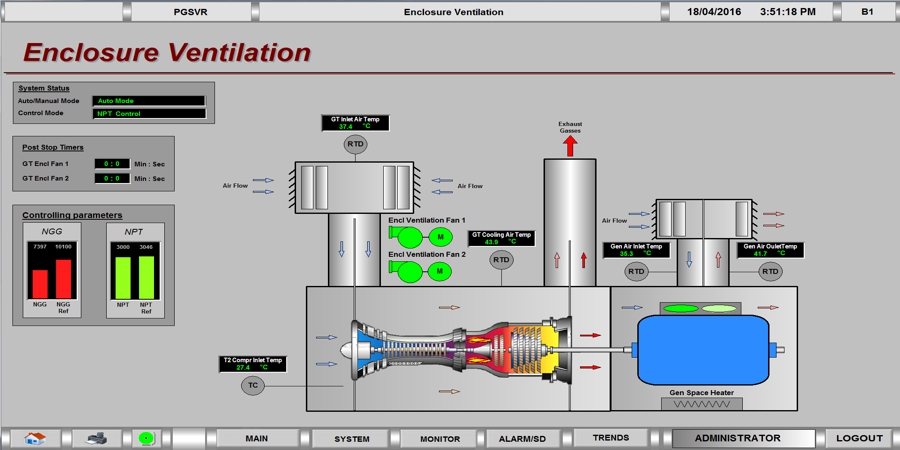

In the two pictures above you can see the System overview of an LM2500 gas turbine and the enclosure ventilation system of the same. These HMI pages were created in GE's iFix package. This software runs on a standard PC and talks using Modbus over Ethernet to a Woodward Governor Micronet + Controller with IO cards.

In this system the whole start, stop and generation of the LM2500 is managed by the Micronet + controller and operators can monitor and trend machine operation from the iFix displays. Other system installed by Gensrv include Citect SCADA, Operate IT (ABB) and T3000 (Siemens).